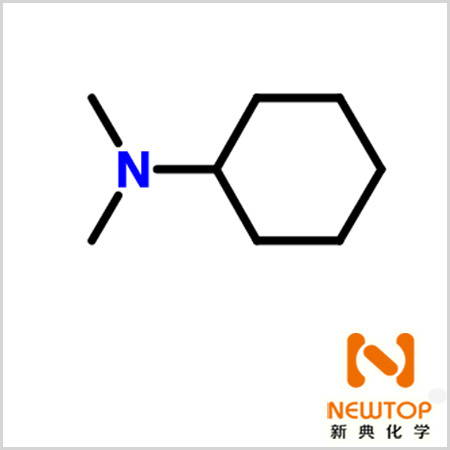

Dimethylcyclohexylamine/DMCHA

Overview:

N,N-Dimethylcyclohexylamine is a low viscosity, moderately active amine catalyst for use in a wide range of rigid foams. One of the main applications is in formulations for insulation foams, spraying, panels, laminates, in-situ infusion and refrigeration, etc. N,N-Dimethylcyclohexylamine is also suitable for the manufacture of rigid foam furniture frames and decorative components.

Synonyms:

Dimethylcyclohexylamine, DMCHA, N,N-dimethylcyclohexylamine, CAS: 98-94-2, Polycat 8, Niax C-8, Catalyst PC8, Catalyst PC-8, Polyurethane Catalyst PC-8, Rigid Foam Catalyst PC-8

Chinese name N,N-Dimethylcyclohexylamine

English Name N,N-Dimethylcyclohexylamine

Chemical formula C8H17N

Molecular weight 127.23

CAS No. 98-94-2

Melting point -60℃

Boiling point 158~160℃

Water solubility 10 g/L

Density 0.849 g/mL

Appearance Colorless or light yellow transparent liquid

Flash Point 108℉

Application: Special catalyst for hard foam

Application

The product 3, especially suitable for the preparation of two-component system, can be dissolved in many hard foam polyol and auxiliaries, in the combination of materials, stable performance, no need to add organotin, moderate activity, adjustability, and can be stored for a long time. In the large-capacity refrigerator combination material, add the appropriate amount of LCA-1, LCA-3, it can improve the flow performance of the foam. The general dosage of hard foam is about 3% of polyether, and auxiliary catalyst can also be added according to the requirements of products. The product has ammonia flavor and bitter taste, irritation to the skin, a certain degree of toxicity, the production must wear good protective equipment.

Dimethylcyclohexylamine DMCHA is a low viscosity medium active amine catalyst, used for refrigerator hard foam, sheet, spraying, on-site filling polyurethane hard foam.DMCHA catalyst has catalytic effect on both gel and foam, Dimethylcyclohexylamine provides balanced catalytic performance for foam and gel reaction of hard foam, and it has moderate catalytic property for the reaction between water and isocyanate, DMCHA is a strong initial catalyst for foam reaction. DMCHA can be used as a stand-alone catalyst, but it is generally used together with other catalysts. Depending on the reaction rate and foam properties, the amount of DMCHA per 100 parts of polyether polyol ranges from 0.5 to 3.5 parts. In addition to hard foam, N-Dimethylcyclohexylamine DMCHA can be used as auxiliary catalyst for molding soft foam and semi-hard foam.

N-Dimethylcyclohexylamine DMCHA is mainly used as the catalyst for rigid polyurethane foam, but also has a wide range of other uses: it is also used as a stabilizer for fuel oil to prevent the formation of oil residue; at the same time, it is also a stabilizing additive for the petroleum distillate of 150-480 ℃; and it is also used as the raw material for pharmaceuticals and pesticides as a biocide, a disinfectant, an equalizing agent, and an antistatic agent, and so on.

Storage and transportation:

Should be sealed and stored in dry, cool and ventilated warehouse

Impact on the environment:

-

Health hazards Invasion route: inhalation, ingestion, percutaneous absorption. Health Hazard: This product has strong irritation to mucous membrane, upper respiratory tract, eyes and skin. After inhalation, it can cause death due to spasm, inflammation and edema of the larynx and bronchial tubes, chemical pneumonitis or pulmonary edema. Burning sensation, coughing, wheezing, laryngitis, shortness of breath, headache, nausea and vomiting occur after exposure.

-

Toxicological Information and Environmental Behavior Acute toxicity: LD50 348mg/kg (rat oral); LC501889mg/m3 2 hours (rat inhalation)

Hazardous Characteristics:

Flammable when exposed to open flame and high heat. Reacts strongly with oxidizing agents. If exposed to high heat, the pressure inside the container increases, there is a danger of cracking and explosion. Combustion (decomposition) products: carbon monoxide, carbon dioxide, nitrogen oxide.

Packing:

180KG/drum Storage: it is recommended to store in dry and cool area with proper ventilation. Please fasten the packaging cover as soon as possible after the original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the product performance. Store in a cool and dry place, keep the container sealed and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothing separately and wash before use. Maintain good hygiene practices.

Company Name: |

Newtop Chemical Materials (Shanghai) Co., Ltd. |

Sales Manager: |

Hunter |

E_Mail: |

sales@ohans.com |

Telephone: |

86-021-5657 7831 |

Fax: |

86-021-5657 7830 |

Address: |

Rm. 1104, No. 258, Songxing West Road,

|

Website: |

www.newtopchem.com |

Our Company

Since its establishment, the company has adhered to the service tenet of “integrity-based, customer first”, adhered to customer demand as the focus, market-oriented, adhered to technological innovation, management innovation and service innovation, and constantly implemented lean production, refined management, to provide customers with better products and services! The company has its own factory, research and development base, set up a strict scientific quality management system, and constantly committed to technological innovation, product innovation and management innovation, so as to ensure that our products have a certain competitiveness in the same industry. The factory is located in Jining City, Shandong Province, China, covering an area of 500 acres, and the current production capacity of various types of amines is 5,000 to 10,000 tons per year.

Our Advantages

Strict Quality Management

Our company strictly implements ISO9002 quality management standards and has established a complete quality management system to ensure the long-term stability of product quality.

Efficient Service

Our production is efficient and reliable, so we deliver on time and within delivery deadlines. At the same time, our team is always happy to help customers and strive to solve customer problems in a short time.

Competitive Price

We have long-term services in wholesale Polyurethane catalyst and have established long-term and stable cooperative relationships with many retailers and agents to provide our customers with reasonably priced products.

OEM Available

Our employee team has high R&D capabilities, superb design and development capabilities, skilled manufacturing technology, and rich product application experience, and can also meet OEM business needs.throughout the entire industry chain.